จำหน่ายวาล์ว Fittings Tubes, Pumps, Tank Equipment, Heat Exchangers, Filtration Equipment, Gasket Plate Heat Exchanger, งานถังสแตนเลสเครื่องเปิดอัตโนมัติ,สารเติมเต็ม, ฟิลเตอร์, เครื่องจัดเรียงสินค้า, เครื่องปิดฉลาก, เครื่องติดฉลาก, เครื่องล้างขวด, ปั๊มที่ใช้ในอุตสาหกรรมอาหาร

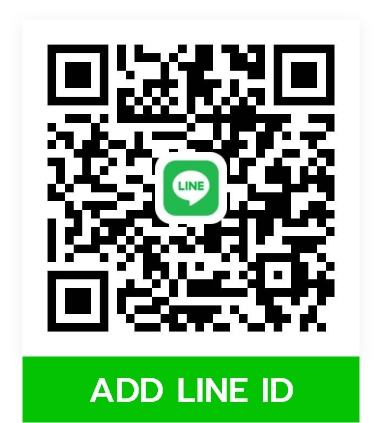

อ่านเพิ่มเติมติดต่อเรา

- 170/5 ซอยประชาอุทิศ 54 แยก 6 แขวงบางมด เขตทุ่งครุ กรุงเทพมหานคร 10140

- +662 1170 913-4

- +662 117 9015

-

mesayon@hotmail.com

mesayon@wassertech.net

English

English Thailand

Thailand